For testing new designs of battery holders, MPD has fabricated min-max sized battery slugs. The slugs are a great aid to our engineering staff in several ways:

The minimum maximum, length and

width for common batteries is fairly wide.

|

|

Length |

|

|

Height |

|

|

Alkaline |

Min |

Max |

|

Min |

Max |

|

59.5 |

61.5 |

|

32.3 |

34.2 |

|

|

48.5 |

50.0 |

|

24.9 |

26.2 |

|

|

49.2 |

50.5 |

|

13.5 |

14.5 |

|

|

43.3 |

44.5 |

|

9.5 |

10.5 |

|

|

23.9 |

25.2 |

|

12.0 |

13.0 |

|

|

46.5 |

48.5 |

|

34.5 |

26.5 |

|

|

Lithium |

|

|

|

|

|

|

24.9 |

25.1 |

|

14.5 |

14.8 |

|

|

33.5 |

34.5 |

|

16.0 |

17.0 |

|

|

33.5 |

34.5 |

|

16.0 |

17.0 |

|

|

15.8 |

16.0 |

|

3.0 |

3.2 |

|

|

19.7 |

20.0 |

|

2.9 |

3.2 |

|

|

22.6 |

23.0 |

|

2.2 |

2.5 |

|

|

24.2 |

24.5 |

|

2.7 |

3.0 |

|

|

24.2 |

24.5 |

|

4.6 |

5.0 |

|

|

24.2 |

24.5 |

|

7.3 |

7.7 |

|

|

|

Dimensions shown are mm |

|

|||

|

|

IEC-ANSI standards |

|

|||

UL2069: Issue number 2, October 2001

This UL standard determines if batteries are properly retained by a holder. 50 insertion-extractions of the battery are followed by contact retention, conditioning, vibration and jarring tests. Notable in the test procedure is temperature conditioning with unplated copper slugs.

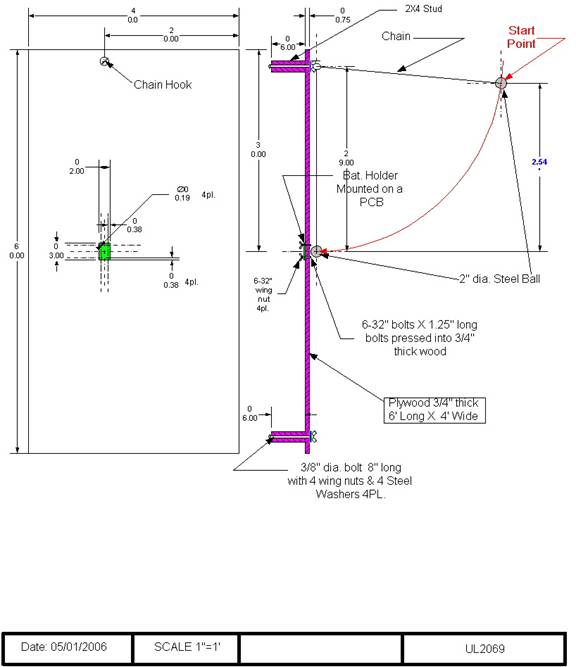

Coin cell battery holder in 60 drop test fixture per UL2069

We used wing nuts for quick mounting of the same PCB to either the jarring or drop test fixtures.

UL2069 Jarring test fixture

PCB is mounted on rear side of ¾ thick plywood board and struck by 2 steel sphere

UL2069 Jarring test fixture mounted vertically

For vertical test the 2 steel sphere is dropped down a tube.

EIA Specification number, EIA-540J000

The purpose of the specification is to provide standard test methods, gages and performance requirements for battery holders. Tests vibration, shock, contact resistance, solderability, temperature/humidity

The major difference between the UL & EIA tests is that continuity is continually monitored during vibration and mechanical shock in the EIA specification. Minor differences are contact resistance and solderability requirements. The EIA also has separate requirements for coin cell holders and cylindrical battery holders, under EIA-540J0AA & EIA540JAB.

ASTM F963, Toy Safety

Coin cell batteries are specifically exempted from the requirements. Limited requirements for a battery holder as the standards focus is on markings, circuit protection, harness wiring and limiting access to batteries without tools. Minor requirements for the battery holders connectors and wires flammability rating, V-0 and insulation heat resistance.

UL913

Intrinsically safe apparatus, ANSI/UL. If you need to meet this requirement, contact our engineering dept or a professional industrial designer or engineering company.

|

Electronic Industries |

Description |

Contact |

|

ANSI/EIA-540J0000 |

Generic

spec of battery sockets. |

|

|

ANSI/EIA-540J0AA |

1/2A,

2/3A, A, AA battery holders |

|

|

ANSI/EIA-540J0AB |

Coin cell

battery holders |

|

|

|

|

|

|

ASTM International |

|

|

|

ASTM F963 |

Toy

safety standard |

|

|

|

|

|

|

BatteryHolders.org |

|

|

|

|

|

|

|

|

|

|

|

Memory Protection Devices |

|

|

|

Technical

Area |

Designs

and application tips |

|

|

Index |

Contact,

cross reference, FAQ, forms |

|

|

|

|

|

|

Underwriters laboratories,

Inc. |

|

|

|

UL2069 |

Coin, AAA

to D cell battery holders |

|

|

UL913

(CSA157) |

Intrinsically

safe apparatus, ANSI/UL |

|

|

|

|

|

|

|

|

|

|

USPTO |

Hundreds

of US patents |

Product Safety Compliance

Batteries are considered safety critical

components by compliance laboratories. A properly designed circuit with reverse

current charging protection of lithium batteries is required, typically two blocking diodes in series or a voltage

blocking component plus a current blocking component (diode-resistor

combination). Plastic components like battery holders have safety requirements

when part of a circuit containing any kind of battery or battery charging

circuits. MPDs drawings contain the necessary information to make your

collecting of documentation for product safety easier.

Design Considerations Checklist